SUSTAINABILITY Customer Relations

Efforts to Ensure Safety and Security

Providing safe and secure food products and meeting the needs for health are essential to Lawson's Three Promises and are important responsibilities that we must fulfill. Our headquarters and stores are working together to deliver safe, secure, healthy, and delicious products to our customers.

Approach to Safety and Security

Lawson complies with environmental and safety laws and regulations in all processes, from the development of original products* to the manufacturing process and sales, and is committed to thorough quality control.

Efforts to Ensure Safety and Security

In order to maintain the quality of our original products throughout all processes, from development to manufacturing and delivery to the customer, our quality control and product development departments, as well as our business partners, work together to implement strict quality control, from raw material management at the time of purchase to production management at the time of manufacturing, guidance to contract manufacturing factories, and hygiene control at our stores. For example, at factories that manufacture original products such as rice products and desserts, we practice hygiene management based on the HACCP concept in order to prevent incidents such as food poisoning and contamination by foreign substances. All important control items in the production process, such as cooking time and product temperature control, are recorded, and if a problem should occur, we have a system in place to immediately investigate the cause and take action.

* Original products: Lawson original products include lunch boxes, rice balls, sushi, bakery items, prepared food, salads, cooked noodles, pasta, and desserts with the Lawson mark on the price sticker.

To Provide Safe and Secure Products

We are committed to achieving safety and security by ensuring thorough quality control.

Use of raw materials

Lawson's original products use carefully selected raw materials and are delivered to customers through rigorous safety and security check systems.

We use safe and secure raw materials that are carefully selected by specialists for the selection process, supplied from factories that have passed stringent screening based on Lawson’s quality control standards. In addition, factory hygiene management and allergen management systems are regularly checked through guidance and audits.

From product design to commercialization

For original products, Lawson conducts its own inspections of the ingredients and finished products, and only those products whose safety has been ensured can be released onto the market. Once the product specifications are finalized, we conduct a document review as well as a trial production on the actual production line to confirm the safety of the product.

Product manufacturing process

At factories that manufacture original products such as rice products and desserts, we practice hygiene management based on the HACCP concept in order to prevent incidents such as food poisoning and contamination by foreign substances. All important control items in the production process, such as cooking time and product temperature control, are recorded, and if a problem should occur, we have a system in place to immediately investigate the cause and take action. Whenever a new factory is put into operation or new equipment is introduced, if needed staff from the quality control department is present to check for any hygiene control problems.

In the daily manufacturing of products, our factories are always kept clean, and employees are required to take air showers, wash their hands, and disinfect their hands before entering the factory to prevent the introduction of foreign substances. In addition, the products themselves are inspected at several levels, including using metal detectors to check for foreign substances, and to ensure that they are presented in accordance with specifications.

Temperature checks at stores

In our stores, we practice hygiene management incorporating the HACCP concept, and we check the temperature of our store showcases four times a day to maintain the freshness and quality of our products. In addition, in order to ensure thorough hygiene control, the food hygiene manager at each store conducts self-inspections, and the SV (Supervisor: Store Management Instructor) at headquarters conducts monthly hygiene surveys and provides guidance. In addition, unannounced inspections by an external organization are conducted at all stores nationwide.

Setting the allowable date of receipt and allowable date of sale

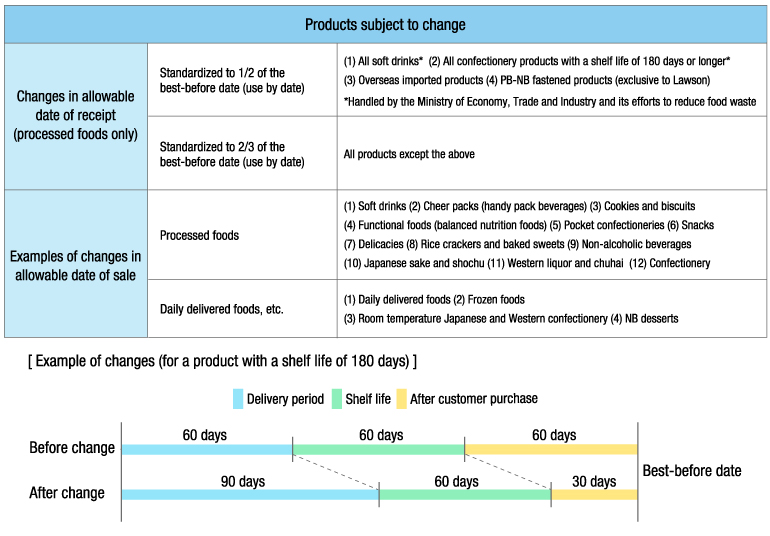

In order for customers to purchase safer products with peace of mind, we set an allowable date of receipt and allowable date of sale for products, and check at our stores to ensure that no products are sold past their allowable date of sale.

Furthermore, as part of our efforts to reduce the amount of food loss, which is considered to be a social issue, we revised 1/3 of the best-before dates (use-by dates) of some processed foods to 1/2 and 2/3. As for the allowable date of sale, we have extended the dates to reduce the number of expired products and to reduce waste.

Training to ensure product safety and security

To ensure the safety and security of our products, Lawson provides training on quality control and hygiene management to MDs (merchandisers), SVs, and other headquarters employees involved in product management. In addition, posters and videos are distributed to stores to alert them to the importance of product quality control and hygiene management.

Training is also provided to employees at plants that manufacture original products such as rice products and desserts to raise awareness of quality control and hygiene management.

●FY2023 Training Results

| Name of training | Eligible employees | Frequency | Number of times/year | |

|---|---|---|---|---|

| Headquarters employees | MD/AMD training | Product Department MD/AMD | 2 time/half year | 7 |

| SV/Trainer/SC* training | SV/Trainer/SC | 1 time/year/person | 22 | |

| Store hygiene survey briefing | Branch managers/SV | As needed | 2 | |

| Franchise stores | Video tool distribution | All member stores | - | 7 |

| Suppliers | Rice products factory training | 76 factories | 10 times/year & area | 85 |

| New supplier screening | New suppliers (designated raw materials, PB products) | - | 130 |

* Store Consultant (SC): A store manager in an MO organization who visits individual stores and provides operational guidance and who has received SC certification from Lawson Headquarters through specified training and examination.